Project introduction

Project introduction

With the enhancement of people's awareness of environmental protection, the development of the world's cleaning industry has brought great challenges, a variety of environmental protection cleaning technology arises at the historical moment, laser cleaning technology is one of them.

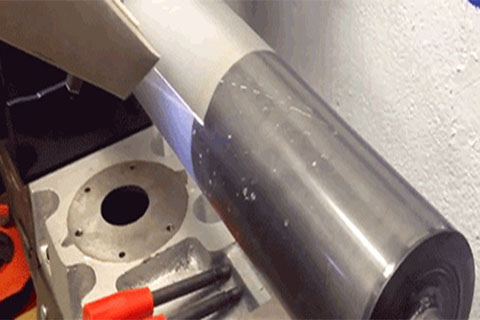

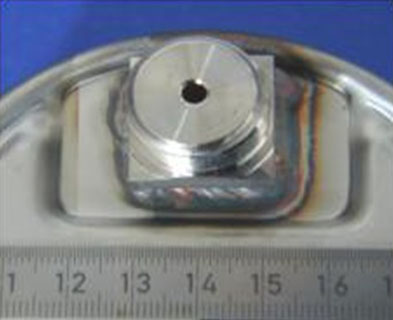

Laser cleaning technology refers to the process of using high-energy laser beam to illuminate the surface of the workpiece to make the surface dirt, rust or coating instantly evaporate or peel off, so as to achieve the cleaning process.

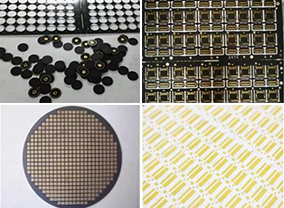

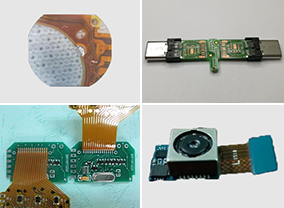

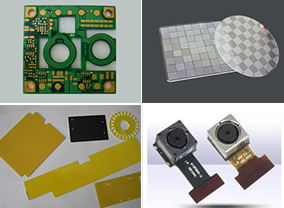

As a novel cleaning technology, laser cleaning technology has been applied in many cleaning fields, such as mechanical industry, microelectronics industry and art protection.

Laser cleaning technology is practical, efficient and has no damage to the substrate. It is a kind of "green" cleaning technology, which causes little pollution to the environment.

It has many advantages over traditional cleaning methods and has a broad market prospect.

|  |  |  |

Cost analysis

Cost analysis

It takes about 5 minutes to clean the laser equipment based on the area of 1m2.

The traditional method takes about 30-60 minutes, and the efficiency is increased by about 5-10 times, which is equivalent to the efficiency of 5-10 people.

A laser cleaning equipment can save about 200,000 to 250,000 YUAN of labor and cost per year.

| Processing way | Laser processing | traditional way |

| Manpower | 1 | 2-3 people |

| Artificial cost | About 50,000 /year | About 100,000-150,000 yuan/year |

| efficiency | soon | slower |

| consumables | N/A | Tools and cleaning reagent, etc |

| Material cost | N/A | About 100,000 per year |

Application cases

Applications

Jiangsu Headquarters:NO.600 Dong Ding Road, Ba ChengTown Kunshan City, Jiangsu Province

Jiangsu Headquarters:NO.600 Dong Ding Road, Ba ChengTown Kunshan City, Jiangsu Province