Project introduction

Project introduction

PCB is an important electronic component, also known as printed circuit board, known as the "mother of electronic products", is the carrier of electrical connection of electronic components.

Its downstream application range is extremely broad, from basic electronic watches, mobile phones, computers and other 3C products, to military weapons, communication equipment, aerospace equipment and so on.

FPC flexible circuit board, in particular, can be said to be the transfusion pipeline for electronic products.

In the modern era of electronic equipment thin, micro, wearable, foldable and other fine direction of the trend, laser technology will usher in a new development.

FPC circuit board wiring density is high, thin, flexible, can be assembled three-dimensional advantages and market development trend is moderately high, laser technology application demand is also increasingly strong.

Cost analysis

Cost analysis

A laser device can produce 4K per hour and more than 80K per day according to 20h calculation.

A product needs 3 sets of supporting positioning jig cost less than 1000 yuan;

The delivery time of fixture is 3 days.

The output of one punch press operated by skilled hands is 2K per hour and more than 40K per day calculated according to 20h.

A product to be equipped with stamping die tooling cost of about 10,000 yuan;

The mold delivery date is 7 days, and the mold repair is tedious.

According to the same production capacity, a laser machine can save 2 people on white night shift, save 4000*2*12=96000 yuan;

Saved mold cost =9000* the amount of projects that can be undertaken by a single equipment;

The short processing time of the fixture can shorten the production time;

The cutting position changes flexibly and quickly.

Flexible response to product modifications.

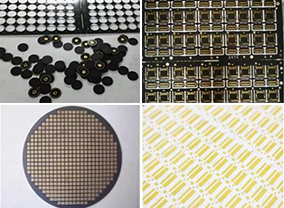

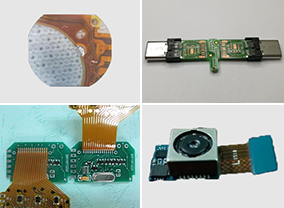

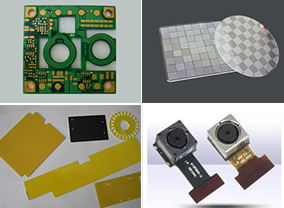

Application cases

Applications

Jiangsu Headquarters:NO.600 Dong Ding Road, Ba ChengTown Kunshan City, Jiangsu Province

Jiangsu Headquarters:NO.600 Dong Ding Road, Ba ChengTown Kunshan City, Jiangsu Province