Project introduction

Project introduction

Automobile industry is a high - tech industry, which needs a lot of processing and testing.

Initially, lasers were used for welding simple cylindrical parts, such as automatic transmission components in vehicles.

Nowadays, laser has been widely used in the processing of vehicle structure.

For example, roof door welding, 3d cutting of forming parts, marking of instrument panel welding, laser welding plate, gear parts, car keys, etc., laser technology can be seen.

So 50 to 70 percent of auto parts are processed by laser.

Therefore, the quality and reliability of laser source are very strict.

Laser technology offers greater benefits in cutting, welding and marking than traditional technologies.

More flexible, easy to automate, can meet the core requirements of the entire industry.

And when the automobile industry develops towards safety, comfort, energy saving and environmental protection, the application of large-scale laser technology becomes more urgent.

Cost analysis

Cost analysis

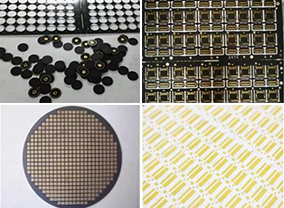

Gear surface marking:

If gear is typed in three equal parts, a total of 18 type 4.

Using the galvanometer marking machine and taking the service life of krypton lamp tube as 700 hours, the overall marking cost of each bearing is 0.00915 yuan.

The cost of electrocorrosion lettering is about 0.015 yuan per piece.

Based on the annual output of 4 million sets of bearings, only marking can reduce the cost by at least 65,000 yuan a year.

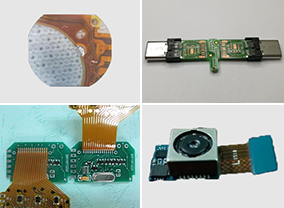

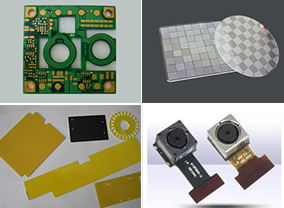

Application cases

Applications

Jiangsu Headquarters:NO.600 Dong Ding Road, Ba ChengTown Kunshan City, Jiangsu Province

Jiangsu Headquarters:NO.600 Dong Ding Road, Ba ChengTown Kunshan City, Jiangsu Province